From Hours to Seconds: Automating Naval Flight Schedules with Data Science

Bottom Line Up Front:

Repetitive, manual tasks quietly drain time across the military. Since these automation efforts are not “flashy,” they rarely get the attention or funding they deserve—even when the return on investment is clear.

In this example, the author developed a Python-based optimization model for a single squadron that automated weekly P-8 instructor scheduling. This automation reduces a weekly 5-hour manual process to seconds and expands the schedule from one day to one week, saving the squadron hundreds of hours annually, not to mention secondary benefits to personnel readiness and morale.

Scaled across the fleet, simple tools like this could save millions and dramatically improve resource utilization, showing that pragmatic automation—not just cutting-edge tech—can profoundly impact warfighter efficiency.

P-8 Poseidon (Source: Military.com)

Purpose

The US military has an automation problem… we do not use it. We require humans to complete redundant tasks that software can solve in seconds. Much of today's rhetoric around automation emphasizes warfighting applications of Artificial Intelligence and Machine Learning—targeting, kill chains, and battlefield decision support. However, this focus neglects the competitive edge that could be gained by applying these techniques to the vast set of tasks across the enterprise of outdated staff work and administrative processes. Automating mundane and error-prone tasks can build efficiency at scale, ultimately saving money and freeing warfighters to focus on lethality. This article shares a recent case study that demonstrates the power of automation in addressing these types of problems.

Aviation squadron scheduling offers a clear example of where straightforward automation can deliver immediate gains. Any servicemember in a planning role can relate to juggling multiple Excel spreadsheets and calendars to produce a feasible training plan. In this instance, that task fell to a Navy pilot who was spending at least five hours each week manually building the flight schedule for his squadron. Repeat this scenario across hundreds of squadrons, and the inefficiency at scale is staggering. As a former Operations Research student at the U.S. Naval Academy, this pilot knew methods existed to provide a better way—but this knowledge was buried beneath years of operational experience. From my position teaching data science and operations research at the United States Naval Academy, I collaborated with him to build a solution.

This project exemplifies how relatively simple, practical applications of automation can drastically improve the daily lives of warfighters. Freeing them from repetitive tasks and providing optimal scheduling of personnel and aircraft creates more bandwidth for training, speeds up the pipeline, reduces waste, and ultimately makes them more mission-effective.

Background

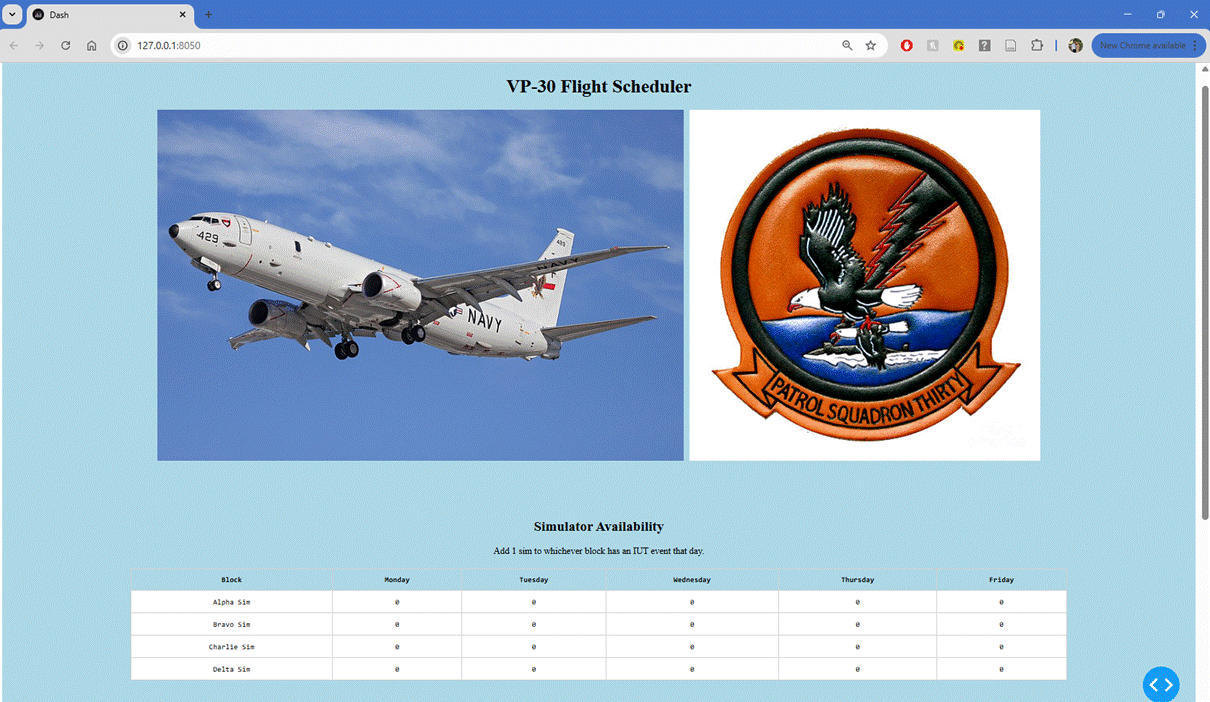

All Naval Aviators begin their training at flight school in Pensacola, Florida, where they learn the fundamentals of aviation by flying training aircraft. Upon graduation, they report to a new squadron to train on the specific aircraft they’ll operate in the fleet. For the P-8 Poseidon community, that squadron is Patrol and Reconnaissance Squadron 30 (VP-30) based in Jacksonville, Florida. VP-30 is staffed by approximately 65 Instructor Pilots (Navy Lieutenants) and a few civilian contractors, who teach students through simulator sessions and training flights.

Problem

As in most Navy and Marine Corps squadrons, building the flight schedule is a highly tedious task. Each day of the week requires a comprehensive schedule to enable the squadron’s 65 pilots to meet their training requirements, which might include as many as ~12 flights, ~13 simulator sessions, and multiple classroom presentations. A good flight schedule must also balance a variety of other planning factors, including the number of flights and simulators available each day, discretionary personnel non-availability, pilot seniority, and mandatory constraints like required crew rest.

For VP-30, the officer in the operations section spent approximately 5 hours a week balancing multiple Excel documents just to generate the flight schedule one day in advance.

Solution

This problem of optimal scheduling is a textbook example from the field of operations research, a discipline that originated in the military and has since been adopted across virtually every major industry. It applies mathematical modeling and computer programming to find optimal solutions to tedious problems like the one faced by VP-30.

In this case, a specific type of mathematical model called an Integer Linear Program was developed to generate the optimal flight schedule. Integer Linear Programs are well suited to solving complex scheduling and assignment problems like those often faced by the military, and many similar projects have leveraged linear programming models to generate immense impacts against real-world operational problems. For example, this thesis project from the Naval Postgraduate School leveraged an Integer Linear Program to assign enlisted Marines to their “best fit” military occupational specialties at the recruit depot – another manual process effectively reduced from hours to seconds in duration. Once adopted, this model decreased the time new Marines spent training before making it to the fleet, and now serves as an example of how mathematical modeling can help deliver value against soft targets like generating talent management efficiencies.

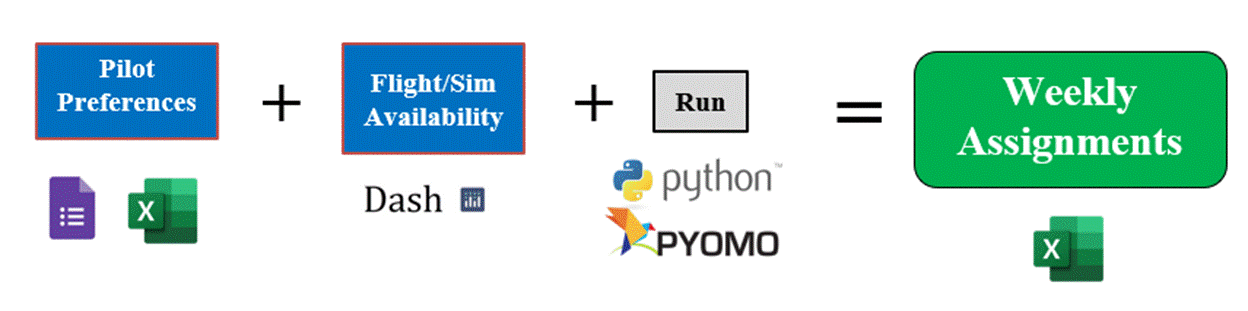

Whether scheduling Naval Aviators or enlisted Marines, an Integer Linear Program offers far greater efficiency and accuracy than manually balancing spreadsheets. In the solution developed for VP-30, the underlying mathematical model—coded in Python—is embedded in a user-friendly Dash web application. Each week, the VP-30 team collects pilot preferences via a Google Form, uploads the responses into the app along with flight and simulator availability, and simply clicks the Run button. Within three seconds, the model produces an optimized Excel schedule for all instructors for the upcoming week. While the interface could benefit from some basic graphic design improvements, the automation dramatically simplifies what was once a time-consuming manual process.

This practical application of automation reduces a five-hour manual process into a three-second process that expands schedule predictability from one day to one week. As of March 3, 2025, VP-30 is using this application weekly.

The Navy and Marine Corps flight school pipeline takes 3-4 years of training before pilots become effective. The compounding effects of operational inefficiencies like the one solved for here unnecessarily lengthen the pilot training pipeline, wasting time and money, and potentially discouraging interested candidates from pursuing careers as pilots. The most immediately measurable impact of this solution is the time saved by the scheduler, but this system is also more flexible than manual methods in cases where a sudden change in resources requires the schedule to be re-generated, such as in cases where a simulator suddenly requires maintenance or pilot availability changes. A flexible, automated scheduling solution ultimately provides greater predictability for pilots when scheduling their training outside of the cockpit, and could ultimately accelerate the pipeline for placing fully trained pilots in operational units.

Conclusion

Simple automations, scaled across units and services, have compounding effects on mission readiness.

It is crucial to leverage both military and industry capabilities to bring the full range of technology to bear on increasingly complex warfighting problems. However, at the tactical and small-unit levels, the daily grind still consists of tasks like building training plans, coordinating resources, and getting the schedule out. These tasks are necessary, but create constant demands on overworked staff, remove cognitive bandwidth from other tasks, and result in the inefficient use of resources.

Automation does not need a tech breakthrough – the tools already exist. Automation is far better suited and much more efficient than humans to handle repetitive, time-intensive processes like those described above. By offloading these tasks, leaders free up cognitive bandwidth to focus on higher-level priorities, such as identifying competency gaps within their units and planning targeted training to address those deficiencies, ultimately increasing combat effectiveness and lethality.

Major Ryan Martinez is a Marine Corps Infantry Officer from Dallas, TX. He graduated from the US Naval Academy in 2015 with a Bachelor of Science in Operations Research. After commissioning in the Marine Corps, he was stationed at 1st Battalion, 5th Marines in Camp Pendleton, CA. He is a graduate of Naval Postgraduate School, where he earned a Master of Science in Operations Research. Currently, he is serving as a Data Science and Operations Research Instructor in the Math Department of the US Naval Academy.

The views and opinions expressed on War Quants are those of the authors and do not necessarily reflect the official policy or position of the United States Government, the Department of Defense, or any other agency or organization.

Effectively employing simple quantitative tools to free up space for *thinking* and *doing* - well done, Ryan! Kudos for the execution, and thanks to you and the War Quants team for sharing.

This VP-30 scheduling automation is a fantastic example of the efficiency gains hiding in plain sight within routine military processes. Freeing up that cognitive bandwidth is invaluable and underscores a key point for any advanced military: operational effectiveness is also about optimizing the human element in the decision cycle, not just weapon systems. When I analyze PLA C4ISR advancements on my Substack, 'Orders and Observations' (https://ordersandobservations.substack.com/), the underlying question is always how effectively its systems and processes enable rapid, informed decisions. Your work shows how pragmatic automation at the unit level is foundational to that kind of C4ISR agility.